We’re excited to share the upcoming discussion series “Critical Disruptions,” organized by Christian J. Lange at the University of Hong Kong. This series of talks will explore the rapidly evolving role of artificial intelligence in architecture and its potential to critically reshape the discipline and the architect’s role within it.

Abstract:

Computational tools based on artificial intelligence (AI) are advancing fast and becoming more accessible to the industry of Architecture. Since 2022, the profession has witnessed an extraordinary development on architectural representations with applications, such as Midjourney, Dall-E, or Stable Diffusion. A recent RIBA report disclosed that 41% of all UK architects are already using AI in their daily work. The question at stake is whether AI is just another tool at hand in creating architecture, or whether it is, as some say, a disruption to the industry, shaking up the very definition of the role of the architect.

Last semester, the studio “Vary (Strong) | Upcycling public housing via AI” taught by Christian J. Lange and Mono Tung started a first discussion in the Department of Architecture at HKU on how to utilize AI in the discipline. The studio generated some very innovative outcomes by developing novel methods in the design process with the help of AI.

The “Critical disruption” discussion series is a next step in bringing attention to the subject by inviting some architects and designers who have dedicated their work and research in recent years to the subject of AI and to advance its usage in the profession.

Organized by

Christian J. Lange

Moderator

Adeline Chan

AI Researcher & Project Associate, Department of Architecture

Discussant

Christian J. Lange

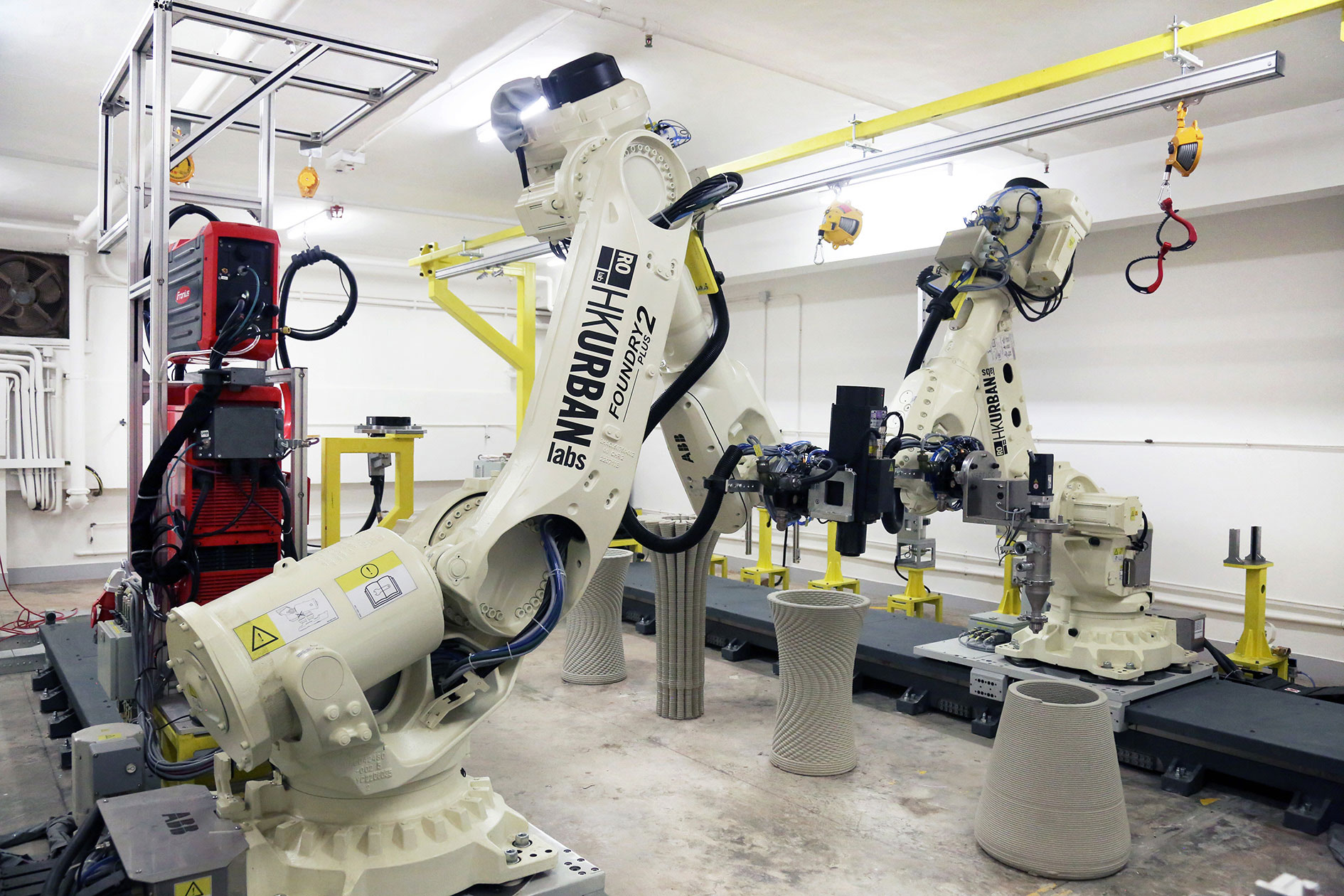

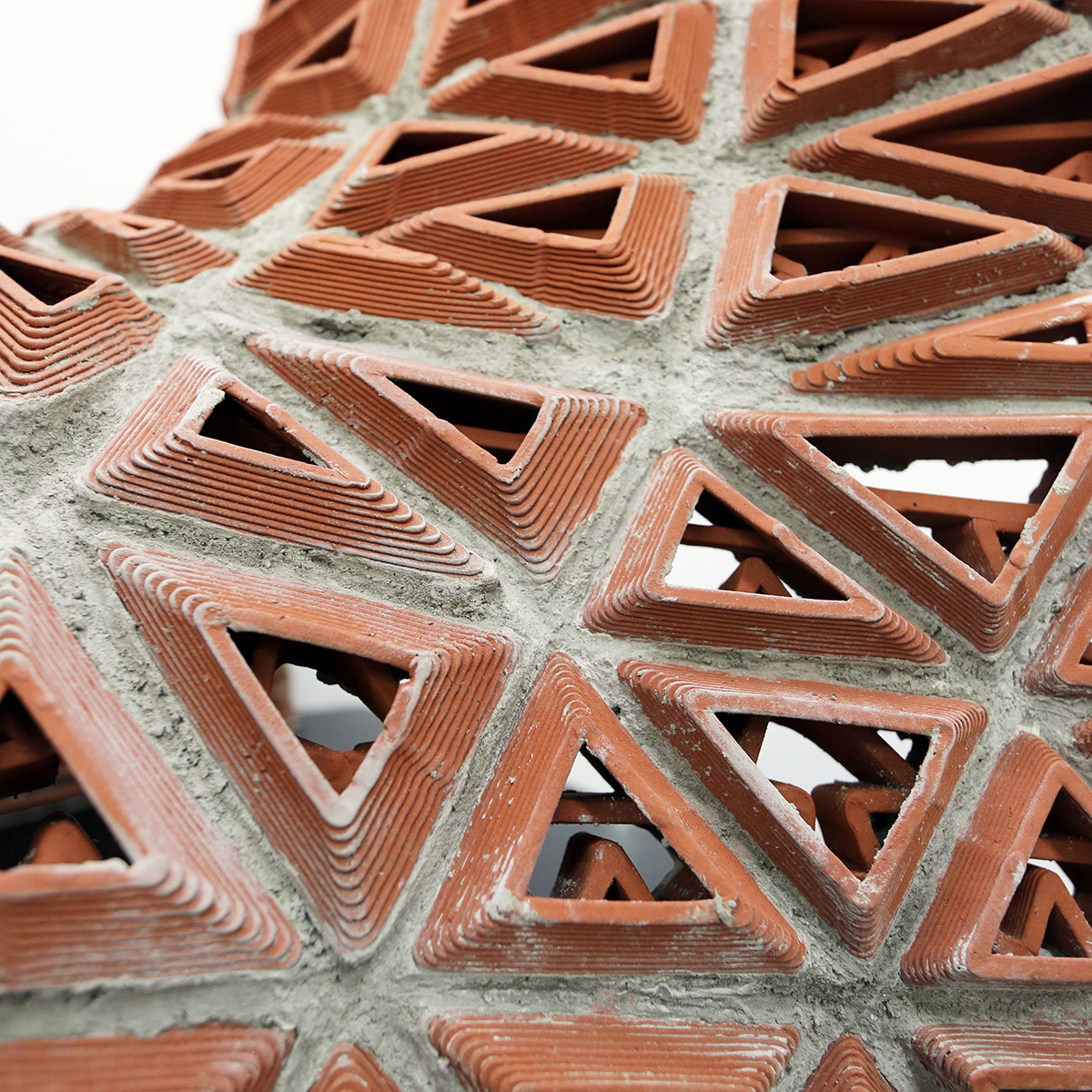

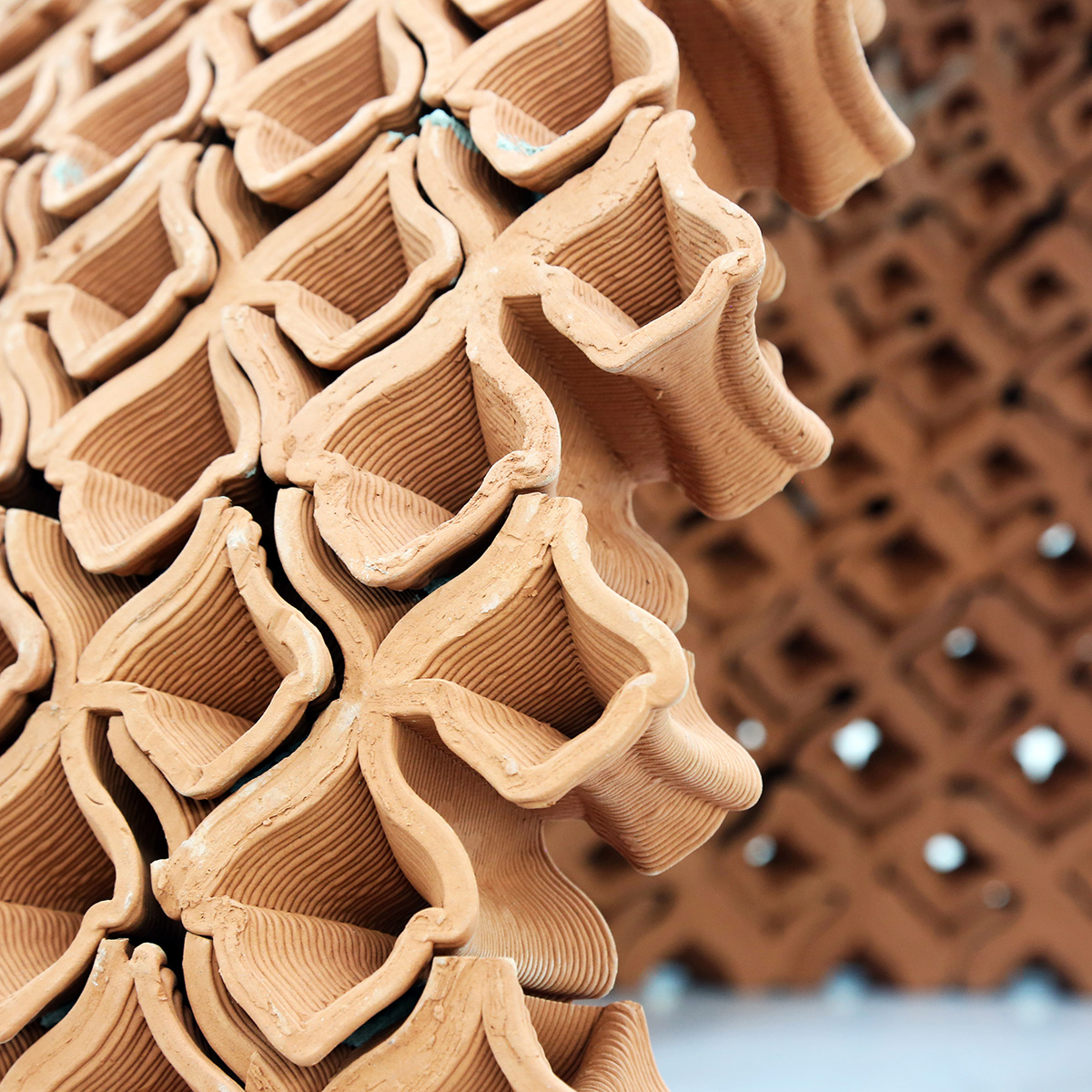

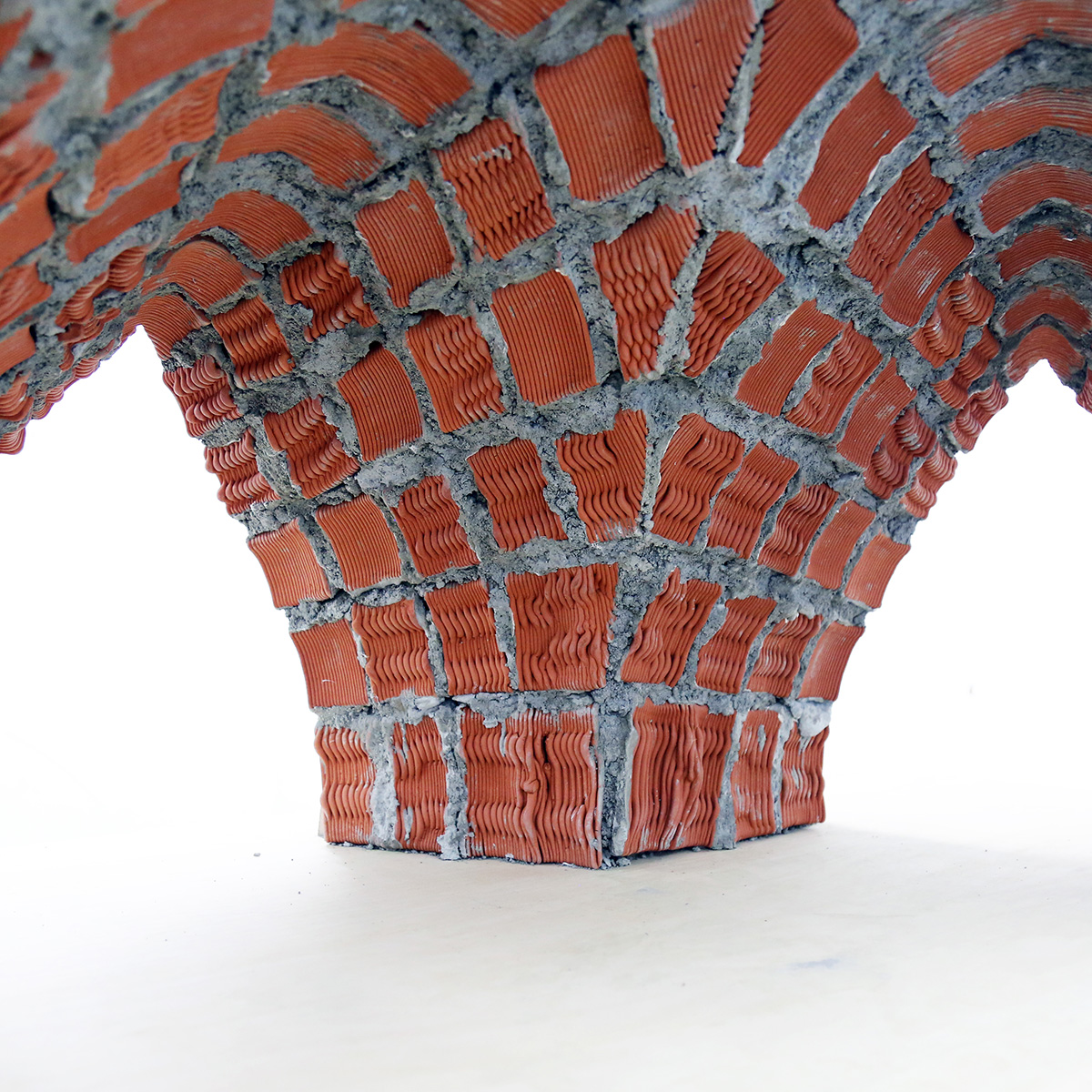

Director of the Fabrication and Material Technologies Lab and Associate Professor (Teaching), Department of Architecture

Discussion Schedule:

Tim Fu 傅倜龍, CEO, Studio Tim Fu (London)

Friday, 12 April 2024, 6:00–8:00pm

Hamid Hassanzadeh, Founder, Parametric Architecture

Tuesday, 16 April 2024, 6:00–8:00pm

Hao Zheng 鄭豪, Director, Architectural Intelligence Group (AIG)

KB419 Lecture Hall, 4/F Knowles Building, HKU

Wednesday, 17 April 2024, 12:30–2:00pm

Carlos Banon, Architect, Associate Professor of Architecture and Sustainable Design, SUTD

Thursday, 18 April 2024, 6:00–8:00pm

Wanyu He 何宛余, Founder and CEO, XKool

KB730 Lecture Hall, 7/F Knowles Building, HKU

Tuesday, 23 April 2024, 1:00–2:30pm

Arturo Tedeschi, Director, Studio Arturo Tedeschi

Thursday, 9 May 2024, 6:00–7:00pm

For more information, please use link below.

https://www.arch.hku.hk/event_/critical-disruptions/?page_num=10