We’re pleased to announce Christian J. Lange’s latest exhibition at PMQ, marking the culmination of his doctoral research completed at RMIT University in spring 2023. Titled Autobryksformation: Towards a New Approach to Brick Expressionism | Methods for Unique Idiosyncrasies in Architectural Material Systems | A Practice in the Making, the exhibition introduces audiences to Lange’s innovative exploration of robotic 3D printing with raw clay. Spanning six years of research at the intersection of architecture and advanced fabrication, the show presents a rich body of work through full-scale prototypes, material experiments, and visual documentation—reimagining the potential of ceramic building components in the architectural landscape.

Abstract:

With a focus on robotically controlled 3D printing methods, this exhibition reflects on the past six years of Christian J. Lange’s research, which culminated into his Ph.D. at RMIT in 2023.

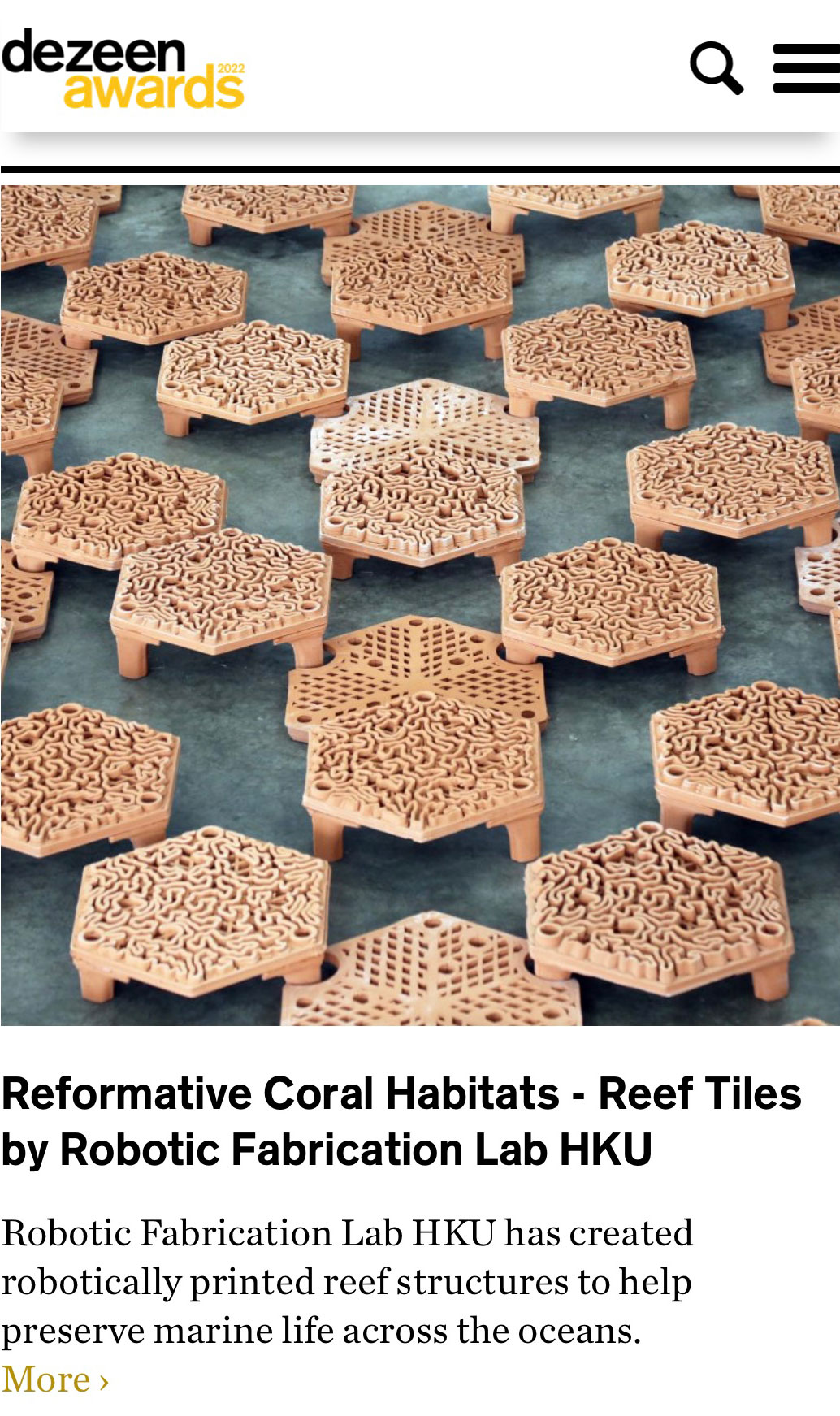

Using raw clay as a base material to innovate form, function, and ornament of architectural ceramic building components, the work on display oscillates between his research in the Robotic Fabrication Lab and his teaching at HKU. The two arenas have become the dominant modes of operation to advance the creative work and constantly influence each other through their specific relationship. The exhibition combines and displays the various projects and approaches in these two streams accumulated throughout the years via physical models, 1:1 scale prototypes, video footage, drawings, and photographs.

Rethinking and revitalizing the 7000-year-old material system of brick, and in particular the brick special (bespoke brick) and other means of ceramic components, the research in this exhibition addresses new modes of production that explore innovative structures, novel performances, and unplanned surface expressions. The work offers alternative answers and applications to the generic, standardized building systems that dominate most of today’s built environment, constrain architectural creativity, and limit innovative design approaches.

The exhibition reveals Lange’s particular approach in this research territory via four lenses that will give a unique insight into the work that offers material solutions for architecture that can be more specific and expressive. The explorations with design-built projects, prototypes, and material experimentations on display unfold and contextualize the methods of making developed successively over time.

Exhibition designed by:

Dr Christian J. Lange

Assisted by:

Adeline Chan

Project Collaborators:

Donn Holohan

Holger Kehne

Dave Baker

Lidia Ratoi

Phil Thompson

Research Assistants:

Tony Lau, Anthony Hu, Teego Ma Jun Yin, Ernest Hung Chi Lok, Chau Chi Wang, Ren Depei, Mono Tung, He Qiye, Henry Ho Yu Hong, Kristy Chow, Pamela Maguigad, Kevin Xi Lin, Nicholas Lau, Leung Ka Chi Alvin, Liu Oui Desmond, Samuel Tam, Tam Chi Yan Jack, Hu Chi Hing Jason, Dominic Co, Chen Jiaao, Chan Ka Chun Tom, Lau Ngai Lam Ellen

Students:

Alexandra Bedin, Milan Nushev, Wiley Ng, Alfred Mak, Shu Ting, Qu Tao, Soo Yeon Bong, Jing Lun Zhao, Jing Jiang, Yingxin Wu, Ho Ka Wing Karen, Cheng Tak Hei Ivan, Victoria Dong, Nicole Biewenga, Fan Xinkai, Hu Chi Hing, Lin Xuancheng, Fan Taiwen, Hong Chen, Lai Chu Tung Jetson, Liu Pui Hang Des¬mond, Wang Youlin, Yam Ka Kit, Chan Ka Chun, Co Dominic Lim, IP Chung Ming, Lau Ngai Lam Ellen, Ma Chun Hon, Tam Chi Yan, Tam Shing Yat, Wang Yi Xiao, Wong Suet Ying, Chan Kwun Kit, Huang Shidan, Liu Tsz Shing, Liu Tsz Yeung, Ng Jian Yao, Tse Wang Chun, Zhang Houzhe, Zhu Chenglin

Venue:

H310, 3/F, Hollywood (Block B), PMQ, 35 Aberdeen Street

Central, Hong Kong

Date:

21-Dec-2023 – 11-Jan-2024

11:00 am – 8:00 pm