The Tidal Stool | A shoreline intervention through a robotic 3D terracotta printing method

I am happy to report the recent installation of a set of tidal stools on the shoreline of Kuk Po village, Sha Tau Kok, Hong Kong. The stool is part of a larger project on the revitalization of of the village and is a critical commentary on the common practice of how we deal with shorelines in Hong Kong.

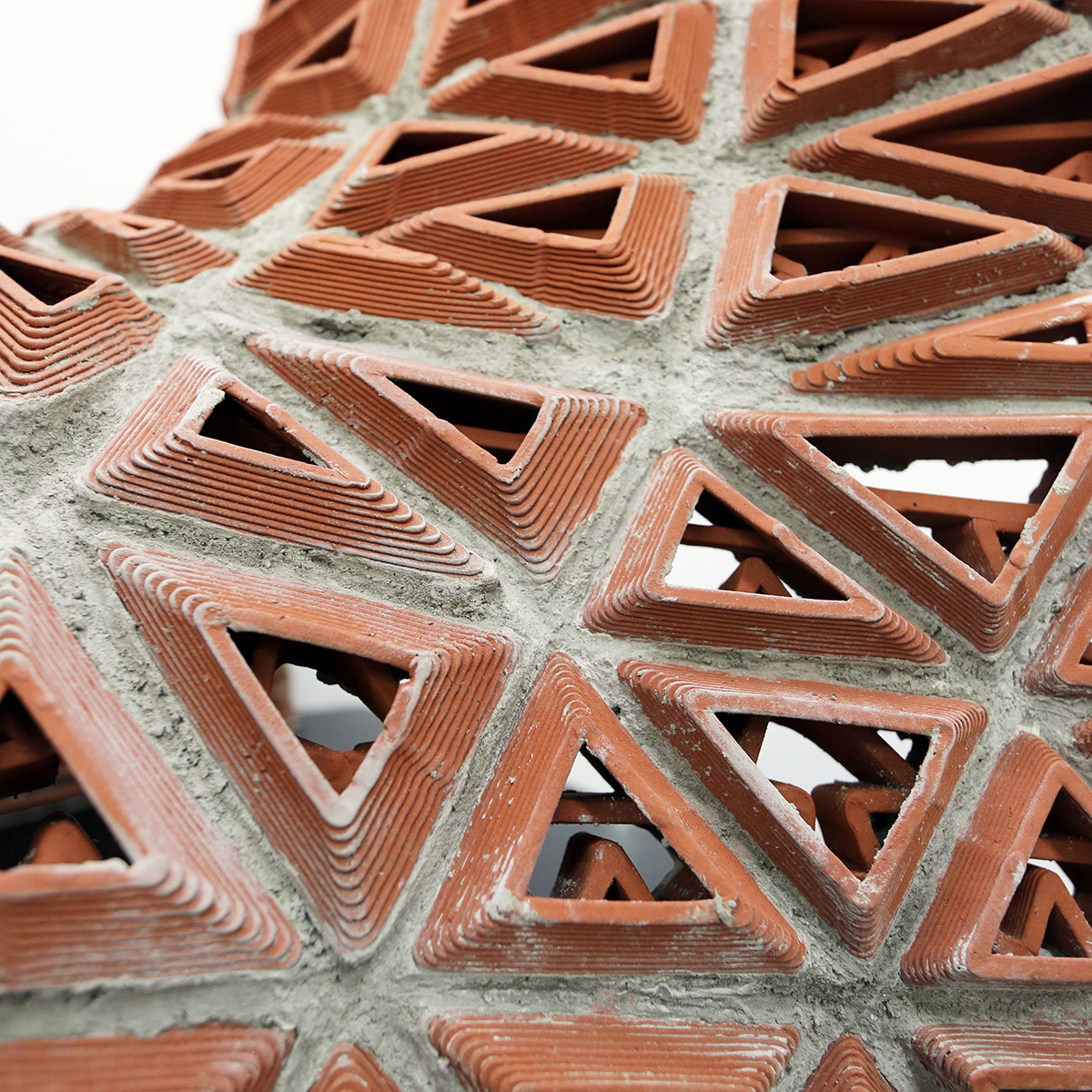

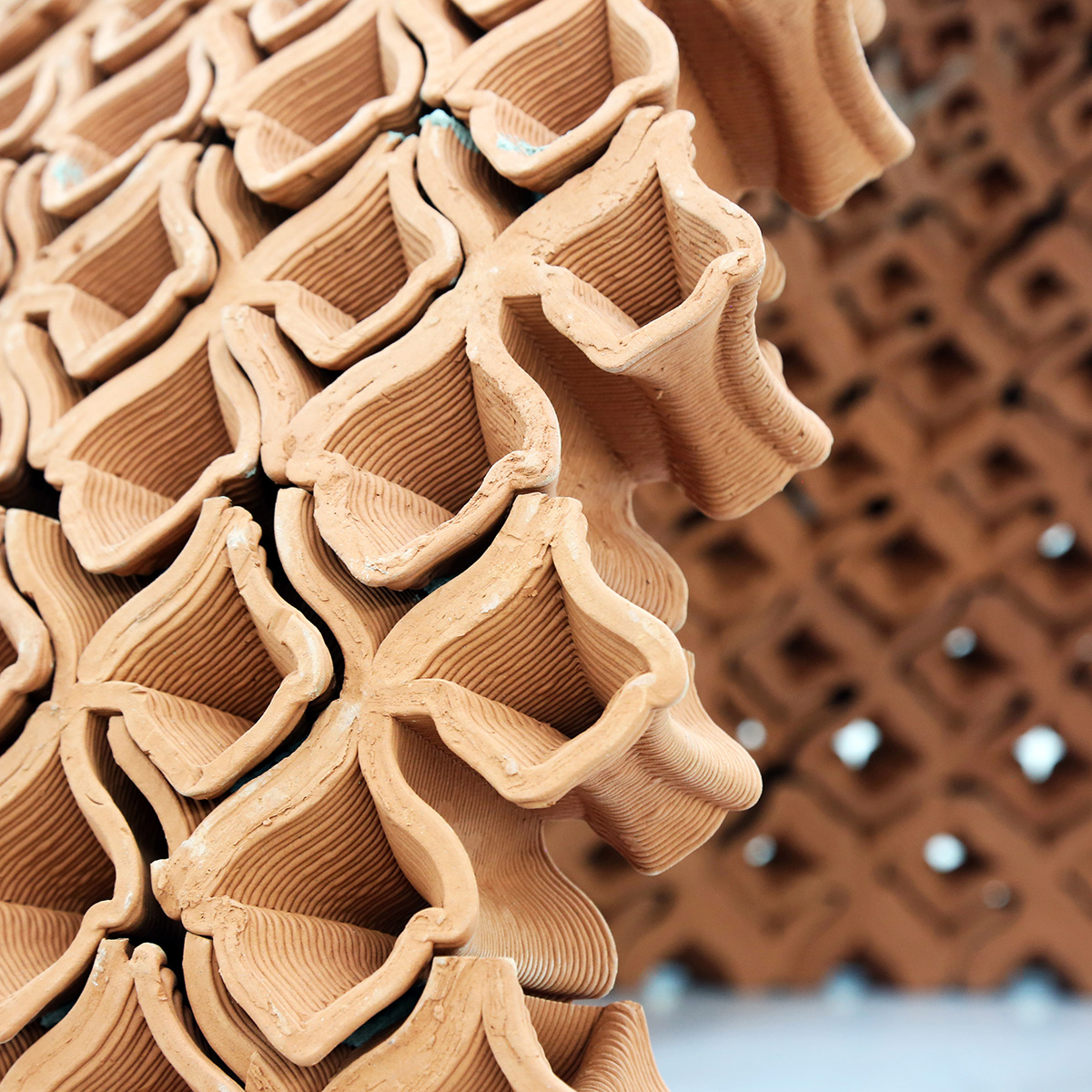

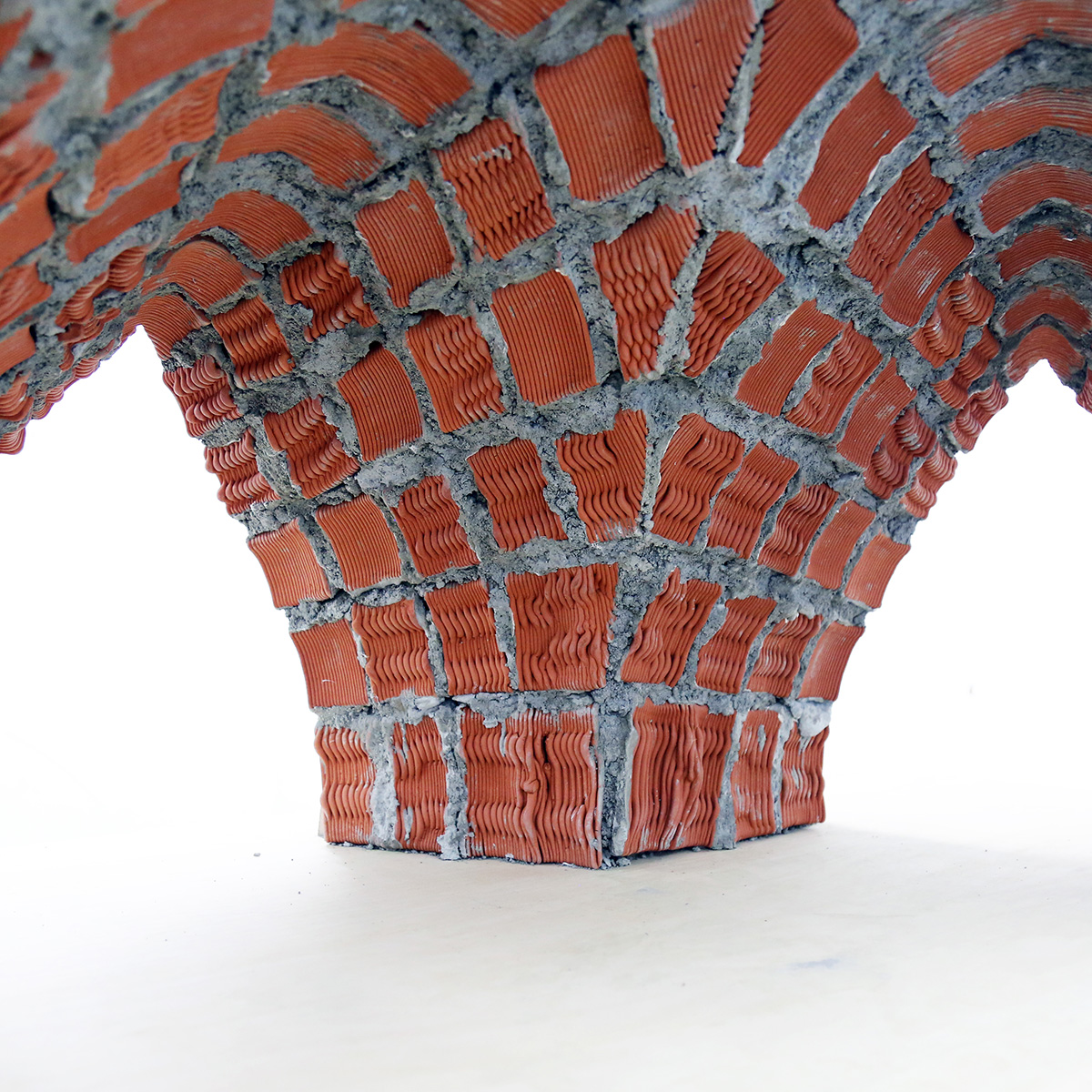

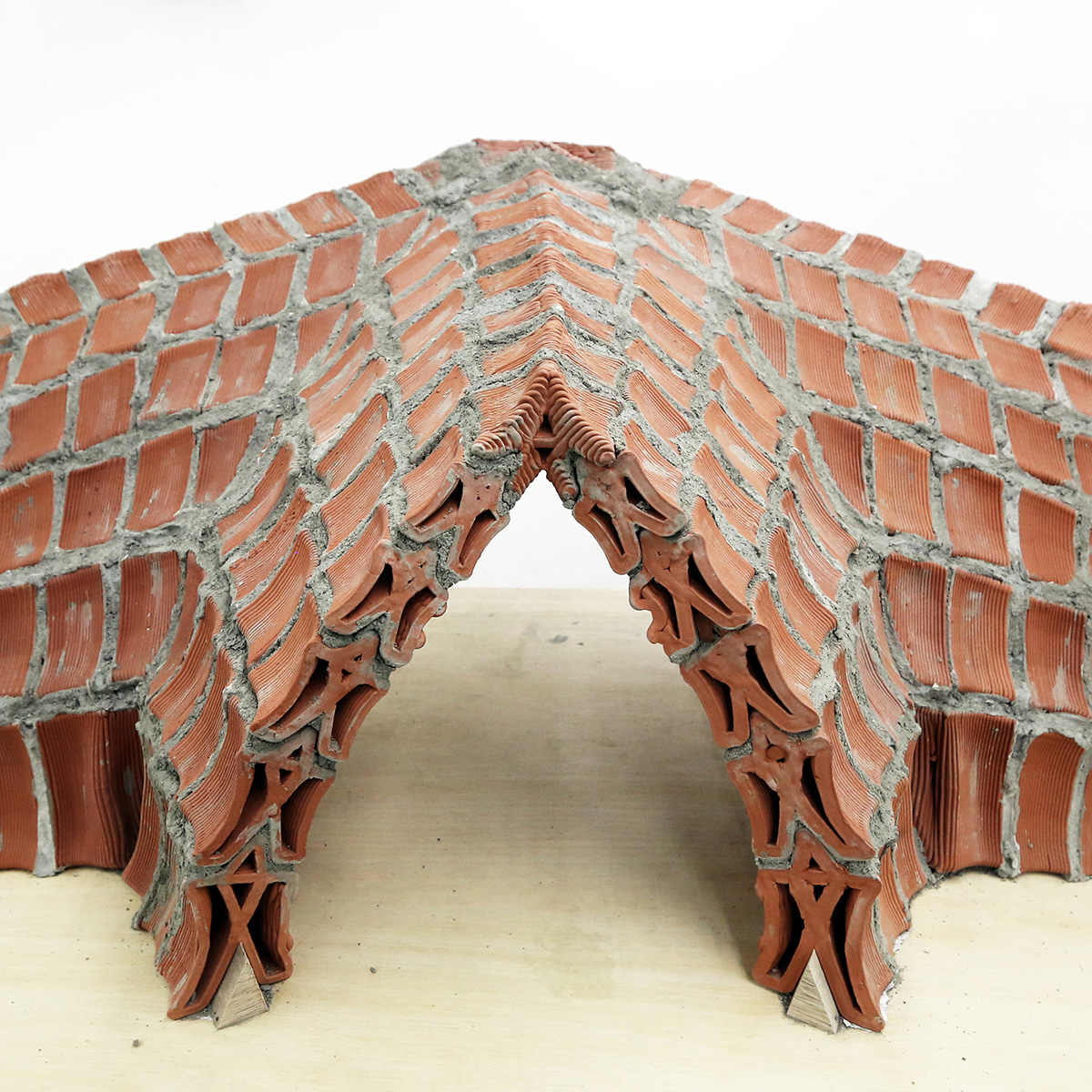

Rather than separating through an artificial intervention, the project brings together two different ecologies, the anthropocentric and the natural environment. Both are the beneficiaries of its functional design approach. With its intricate spaces and crevices, the stool provides for many creatures hide-outs from predators and enhances the ecology of the shoreline. During high tide, the stool is partially submerged in the water. During the low tide, it invites the villagers and its visitors to take a break and enjoy the beach.

Overall, the team produced 30 unique stools with different heights for different users and varying degrees of surface complexity. The goal in producing the multiplicity of solutions was to understand which geometry would, in the end, perform best for the natural environment. All stools were produced using a standard industrial robot. The stools were made using a unique mix of terracotta clay, which is very suitable for natural habitats due to its Ph-level. So, in case the stools deteriorate over time, they get back to nature without any harm.

Funding body: Kuk Po Vision | Country Conservation Office

Project Credits:

Robotic Fabrication Lab | Faculty of Architecture | The University of Hong Kong

Christian J. Lange (Team Leader)

Weijen Wang (Team Leader)

Team:

Chen Zhaowei

Yin Fangyi

Chan Ching Yin