Outcomes of “Autobrickformation“ Studio

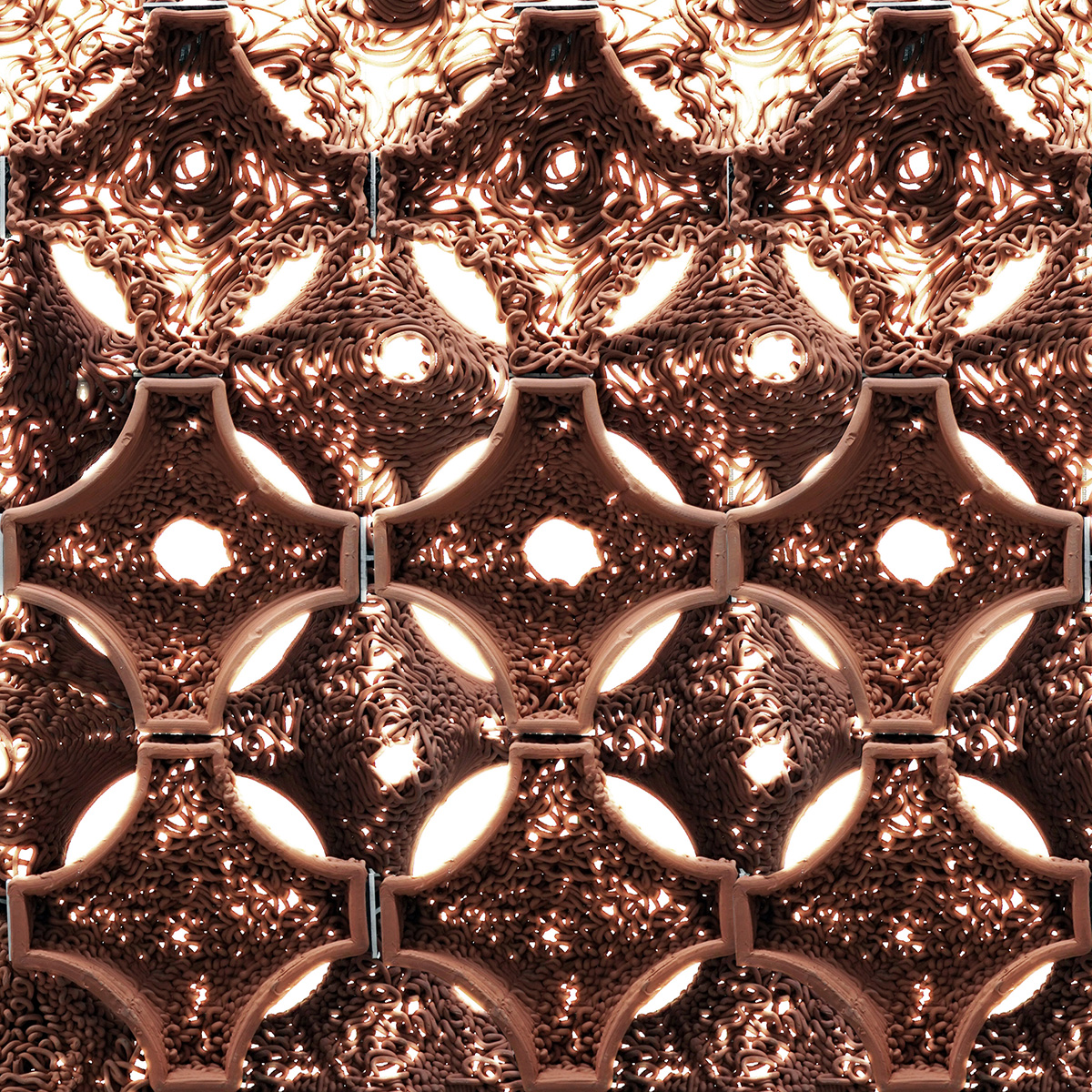

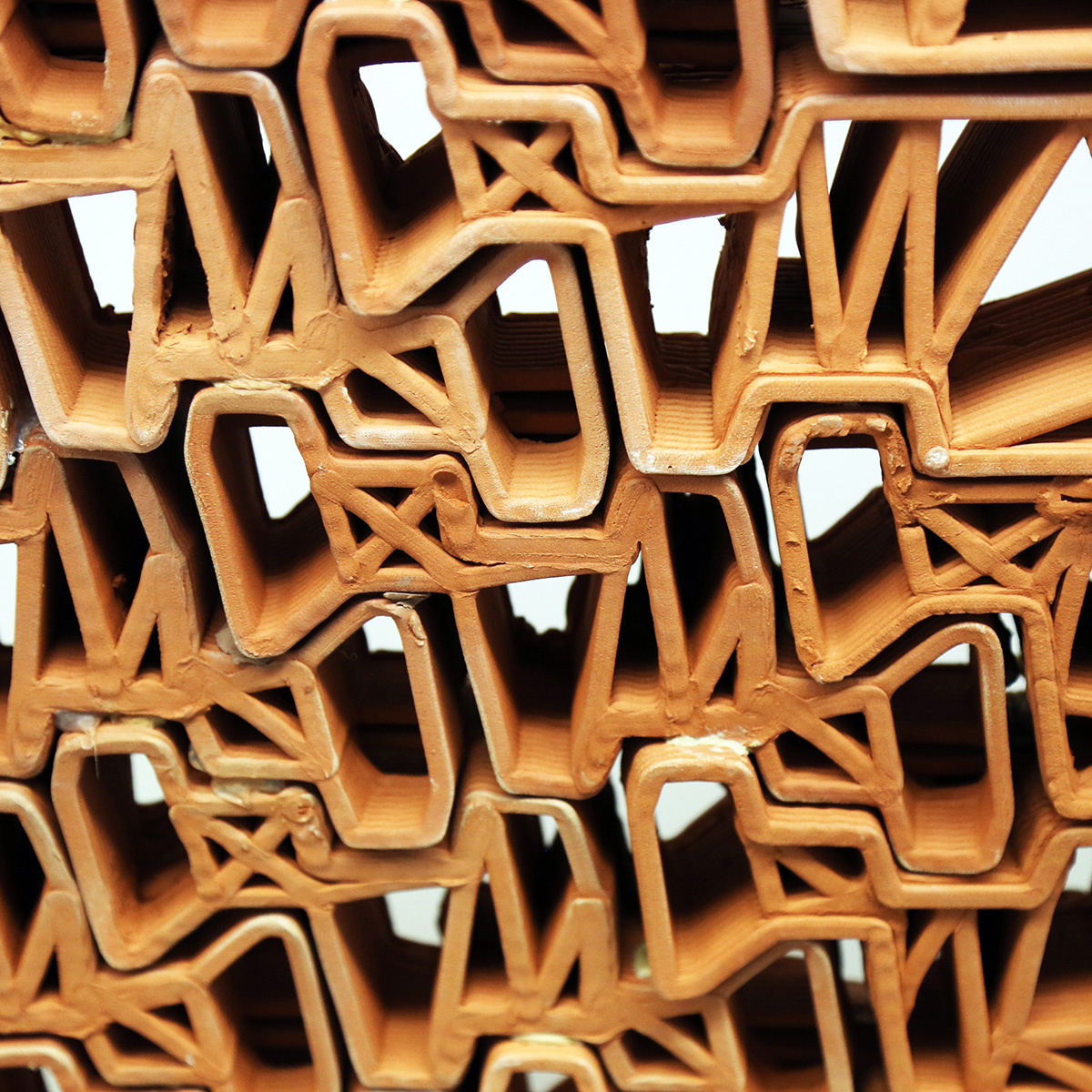

Sunday, January 13th, 2019At last, I would like to show some photos of the outcomes of the latest studio that I taught at The University of Hong Kong. The M.Arch I studio entitled “AUTOBRICKFORMATION” focused on one of architecture’s oldest building materials, the brick.

Below is an excerpt of the brief:

The history of architecture is primarily based on a model of parts-to-whole. One of the oldest building material that is the ultimate embodiment of this concept is the brick. The brick was until modern times the standard component to build mundane buildings around the world. It represents a building material that can be flexibly assembled, is good in compression, and, although it’s based on a standardized logic, has an extensive range of architectural expression. Originally bricks were made through a slop moulding method. Today, most industrially produced bricks are made through a die extrusion process. It’s a fast and economical method but has its limitations in complexity achievable.

In the past decade, 3d printing technology has become more advanced and has made its way into architecture. Many of the industry experts who are driving this development dream of large-scale production with large printers that print entire houses in every shape and form. Though there are quite a few promising developments on the horizon, it is certain that this trend will be only one trajectory of how we think about new technologies to drive contemporary architectural production. The studio therefore will focus on the brick and try to understand how recent technologies can rethink this 7000-year-old building material.

Students: Fan Taiwen, Fan Xinkai, Hong Chen, Hu Chi Hing, Lai Chu Tung Jetson, Lin Xuancheng, Liu Pui Hang Desmond, Wang Youlin, Yam Ka Kit